Lori Kelly: A Woman in Steel

In the fast-paced world of industrial technology, Lori Kelly, Industrial Business Development Manager, stands out not only as an expert in metals processing but also as a female leader in a predominantly male-dominated field. With over 20 years under her belt at Kadant, Lori’s deep understanding of roll cleaning challenges in sheet processing and finishing lines is both impressive and invaluable.

In the fast-paced world of industrial technology, Lori Kelly, Industrial Business Development Manager, stands out not only as an expert in metals processing but also as a female leader in a predominantly male-dominated field. With over 20 years under her belt at Kadant, Lori’s deep understanding of roll cleaning challenges in sheet processing and finishing lines is both impressive and invaluable.

Please join me in a recent discussion I had with Lori about pressing issues in the metals processing industry.

KB: Lori, you have an impressive career in the metals industry. What drew you to this field?

LK: What fascinated me were the challenges with quality and safety issues in the industry. I have always been excited about finding solutions and working with customers, and the metals industry gave me that opportunity.

KB: As a woman with over 20 years of experience, how has the industry changed concerning gender diversity?

LK: It has changed significantly. When I started, there were only a handful of women in the industry. Now, I see a growing number of women actively participating and making a difference. It’s inspiring!

KB: What is your favorite part about visiting a steel or metals processing mill?

KB: What is your favorite part about visiting a steel or metals processing mill?

LK: I love interacting with the customers and understanding their challenges firsthand. Each visit offers new learning experiences and insights into how our products can make a difference.

KB: What leads to defects in metal sheets during processing and why is it important to fix these issues quickly?

LK: Sheet defects in processing and finishing lines are mainly caused by debris such as dirt, oil, or zinc flakes that get embedded on a roll and then transfer to a sheet. If not detected early, this can lead to substantial waste because a portion or entire coil may need to be discarded. It's crucial to address these issues to maintain quality.

KB: What is the most common approach to roll cleaning in metals processing? Are there limitations?

LK: The most common approach is manual cleaning, which is time-consuming and is a safety concern. Many people place roll cleaners where they can visibly see the issue, typically at the end of the process. However, the key is to clean the rolls early in the process lines to ensure the strip is defect-free and high quality.

KB: What revolutionary roll cleaning solutions are you passionate about?

KB: What revolutionary roll cleaning solutions are you passionate about?

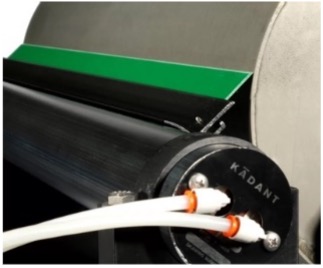

LK: The VeriLite™ roll cleaner assembly is exceptional! With hundreds of installations in metals processing, I’ve witnessed how the compact design is a gamechanger. It provides constant pressure for uniform cleaning and minimizes downtime because there’s no stopping for manual cleaning. It’s safe, efficient, and plays a vital role in addressing quality defects early in the process.

KB: How does the VeriLite roll cleaner assembly contribute to a safer work environment?

LK: The beauty of the VeriLite roll cleaner assembly is that it’s hands-off. Once installed, you can forget about it until it’s time to change the blade. This reduces the need for manual cleaning with hand-tools or homemade scrapers or brushes, which is extremely time-consuming and a safety risk due to all the pinch points.

KB: What are some of the trends emerging in the metals industry in 2023?

LK: The metals industry is experiencing trends focused on strip quality, industrial hygiene, safety, environmental concerns within operations and maintenance.

KB: Lastly, what advice would you give to someone just starting in the metals industry?

LK: Listen and learn. The industry is ever evolving, and it’s vital to understand the needs before your audience does. Be honest, knowledgeable, and never pretend to know more than you do.

Lori Kelly's expertise and valuable insights serve as a reminder of the crucial role women play in driving innovation within the steel and metals processing industry. Her dedication to continuous learning and openness to embracing advanced technologies like the VeriLite roll cleaner assembly demonstrates the path to enhanced productivity and sustainability in the industry. Lori knows what the customer wants, and she advocates for smarter solutions.