Industrial Processing

Our Industrial Processing segment consists of our Wood Processing and Stock Preparation product lines. Our equipment, machinery, and technologies are used to recycle paper and paperboard and process timber for use in the packaging, tissue, paper, wood products and alternative fuel industries, among others.

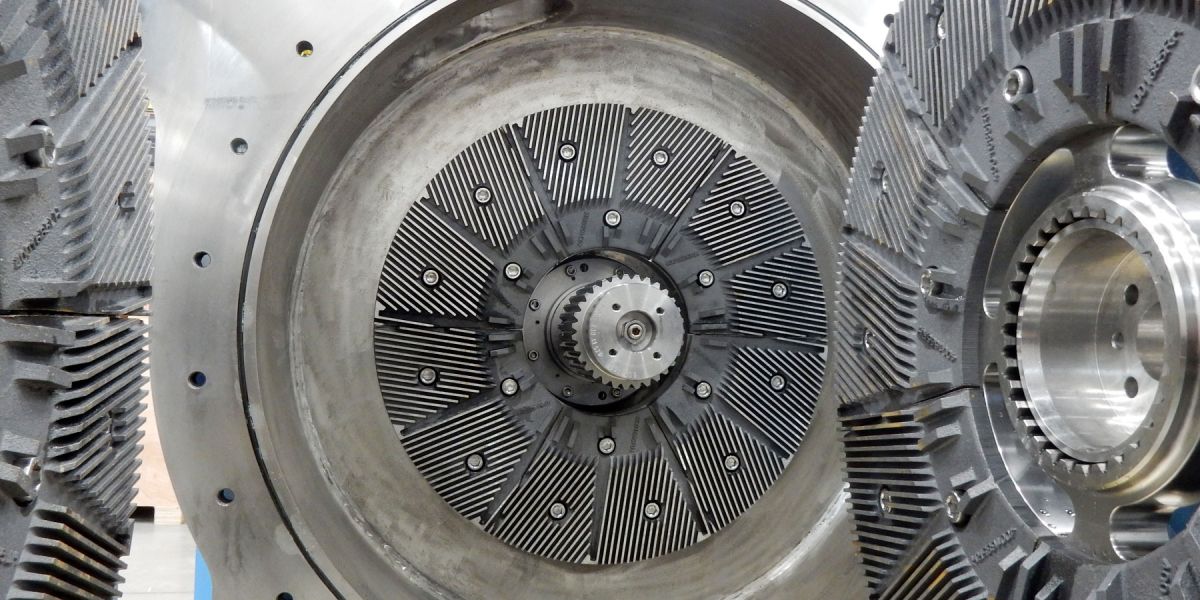

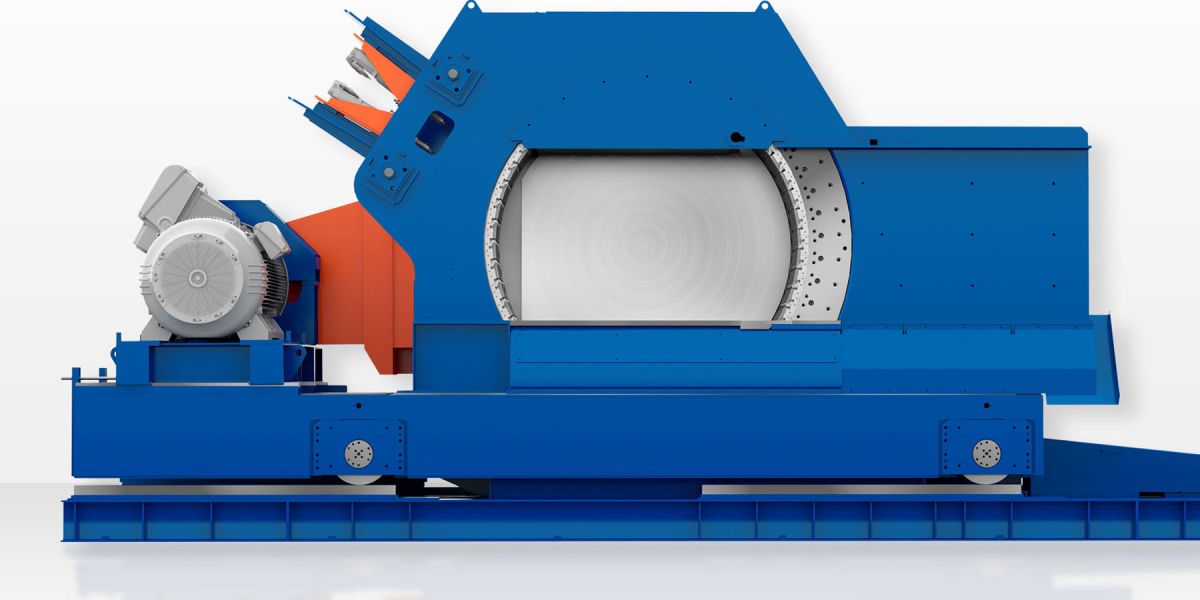

Our brand portfolio includes well-established industry leaders such as Black Clawson, Carmanah, Goslin, Lamort, Nicholson, Noss, and Valon Kone and dates back to 1873. Our primary products include stock preparation systems and recycling equipment, debarkers, stranders, chippers, and logging machinery.

Key Industries

-

Packaging

-

Tissue

-

Paper

-

Metals

-

Wood Products

-

Alternative Fuels