Over-The-Shaft Rotary Union Basics

Where OTS Rotary Unions Are Used

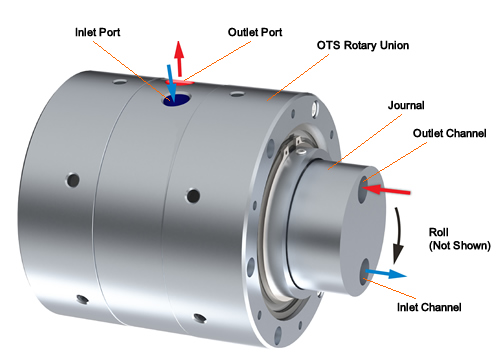

Over-the-shaft (OTS) rotary unions are used with journals (shafts) that contain channels for conveying fluid into and out of rolls. The OTS rotary union seals around the journal and transfers fluid through the channels as the journal rotates. OTS rotary unions are commonly used when the fluid conveyance and drive system are at the same end of a roll. In these cases, the journal must convey fluid and transfers torque. The metal industry commonly uses OTS rotary joints where rolls are cooled with water. But applications are found wherever water, steam, or other fluid transfer is needed.

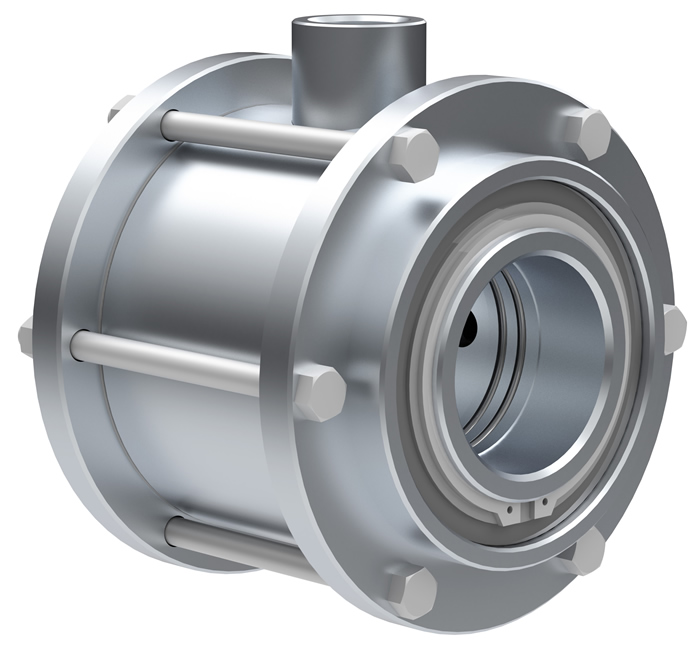

How OTS Rotary Unions Work

OTS rotary unions use ports to move fluid into and out of the journal’s channels. The number of inlet and outlet ports are matched to the number of channels. As ports are added, the OTS rotary union increases in length.

OTS rotary unions use ports to move fluid into and out of the journal’s channels. The number of inlet and outlet ports are matched to the number of channels. As ports are added, the OTS rotary union increases in length.

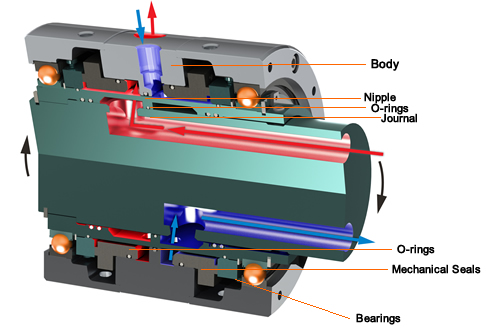

During installation, an OTS rotary union is fit over a customer’s journal and elastomeric-rings seal an internal rotor to the journal. The rotor and journal then rotate as one piece within the stationary housing (rotating components shown in green). The sealing technology between the rotating rotor and the stationary housing is critical to leak-free performance. Most applications use elastomeric seals, while balanced mechanical seals are used in high-speed, high-wear applications. Pressure mechanical seals are used in steam applications and are similar in design to balanced mechanical seals.

Choosing an OTS Rotary Union

The seal technology used in OTS rotary unions is critical to reliable, leak-free performance.

The seal technology used in OTS rotary unions is critical to reliable, leak-free performance.

Kadant Johnson uses DuraSealTM high-performance elastomeric sealing technology as well as proven mechanical seal designs. Kadant Johnson custom designs OTS rotary unions in multiple sizes, configurations, and performance requirements for water, steam, and other fluids. Typical water and steam configurations are shown below.

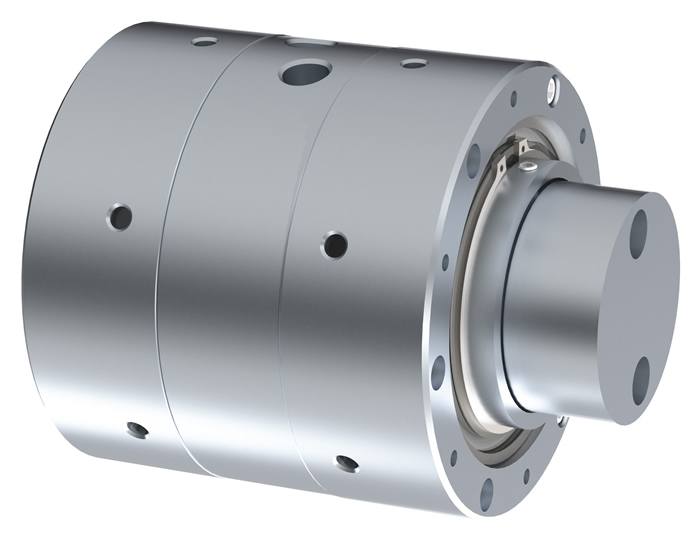

Balanced mechanical seal OTS rotary union

Applications: High-speed

Applications: High-speed- Pressure: 60 psig (4 bar)

- Temperature: 150ºF (66°C)

- Rotation speed: Up to 200 RPM

- Media: Water

- Passages: 1 to multiple

- Balanced mechanical & DuraSeal sealing technology

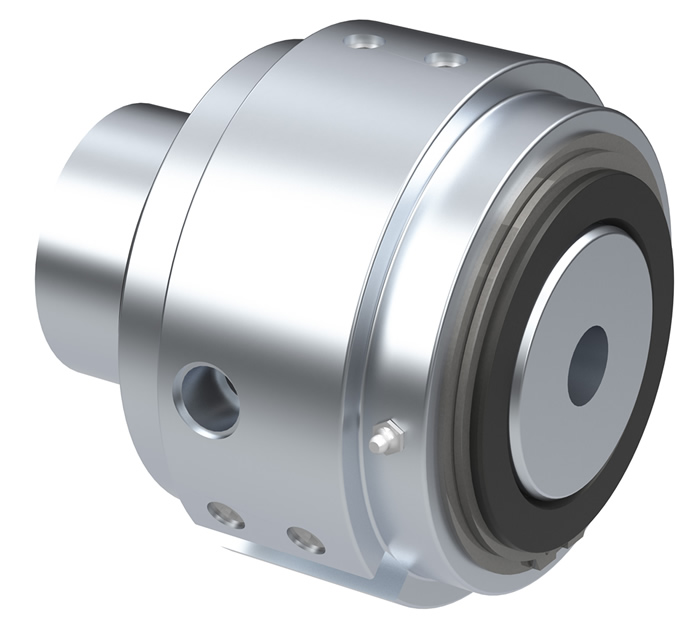

DuraSeal OTS rotary union

Applications: Low-speed

Applications: Low-speed- Pressure: 150 psig (10 bar)

- Temperature: 200°F (93°C)

- Rotation speed: Up to 4 RPM

- Media: Water

- Passages: 1 to multiple

- DuraSeal sealing technology

Pressure mechanical seal OTS rotary union

Applications: Moderate-speed

Applications: Moderate-speed- Pressure: 150 psig (10 bar)

- Temperature: 400ºF (200°C)

- Rotation speed: Up to 50 RPM

- Media: Steam

- Passages: 1 to multiple

- Pressure mechanical seal technology