Choosing the Right PT™ or PTX® Rotary Joint Repair Kit

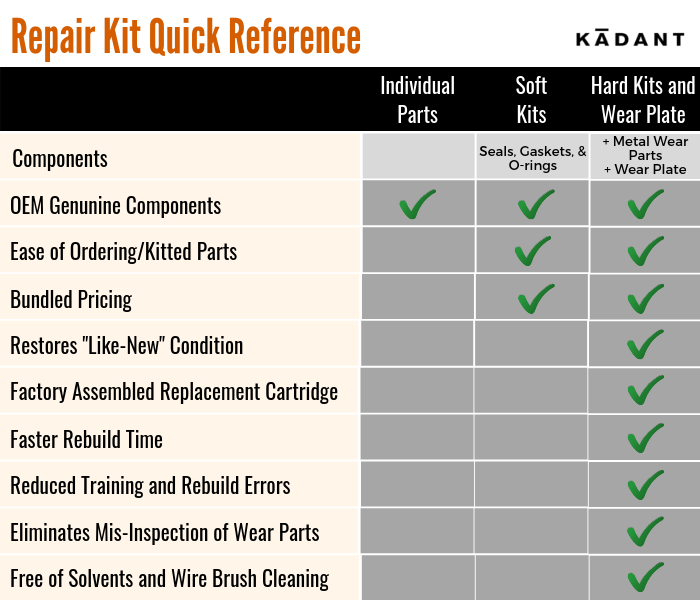

Repairing and refurbishing worn piston type (PT or PTX) rotary joints can restore them to a “like-new” condition while avoiding the cost of a new rotary joint. Customers understand the value of refurbishing rotary joints and using 100% genuine OEM parts, but when it comes to the rebuild, it isn’t always clear which parts to order. Worn parts can’t be identified until the rotary joint is torn down and the rotary joint can’t be rebuilt until needed parts are available. In many cases, worn parts are not easily identified and aren’t replaced, resulting in a rotary joint that is not fully refurbished. Repair kits are a convenient and economical way to ensure quality, performance, and peace-of-mind when refurbishing rotary joints.

Soft Kits

Kits that contain genuine OEM seals, gaskets, and O-rings are referred to as soft kits. These are the most inexpensive kits. They are used when it is known that there has been limited wear and the technicians have been thoroughly trained on inspecting and rebuilding PT and PTX rotary joints. They require the rotary joint to be fully disassembled and the metal parts must still be inspected for wear and repaired if necessary. If worn metal parts are mis-inspected and not replaced, the rotary joint is not refurbished and may fail prematurely.

Hard Kits

Kits that contain metal wear parts in addition to seals, gaskets, and O-rings are known as hard kits. The PT and PTX rotary joints have a modular design and the hard kit is oven referred to as a “cartridge kit” because it can be quickly swapped into a rotary joint as an assembly. When used with a new wear plate, these kits restore the rotary joint to a “like-new” condition with genuine OEM parts. It is faster to rebuild a rotary joint with a hard kit than a soft kit because the technician does not need to dis-assemble, clean, inspect, and reassemble each metal wear part. Additionally, they eliminate the wire brush cleaning, solvents, and mis-inspections associated with metal wear parts. A rule of thumb is that a two-person team will take one-half the time to replace a hard kit versus rebuilding a rotary joint using a soft kit.

Recommendation

Hard kits with wear plates are recommended for most rebuilds. All wear components are replaced with OEM genuine product, it is faster to refurbish, and they ensure the correct parts are replaced. Soft kits are recommended in situations with limited wear and with technicians thoroughly trained on inspecting and rebuilding PT and PTX rotary joints.