Proper Doctoring – The Art and Science Behind Roll Cleaning

For nearly 100 years, Kadant Solutions Division and its affiliate companies have specialized in scraping and removing build-up from roll surfaces. This cleaning process is often called doctoring, roll cleaning or scraping. It is important to note that a well functioning roll scraping system consists of the same basic components as shown in the image above.

While the hardware is important and may represent the science of doctoring, the integration of these components along with proper installation and maintenance is equally critical. Some may call this the art of doctoring.

Why is proper blade angle and alignment critical?

When a roll scraper is not performing well, the initial inclination for operators is to increase the loading force. While this may ultimately be necessary, starting here can lead to premature blade wear or damage the roll surface. If roll cleaning performance is not improved by running a new blade, Kadant Solutions recommends checking the blade alignment and blade angle and then making adjustments to the alignment or angle, as needed, to ensure adequate cleaning.

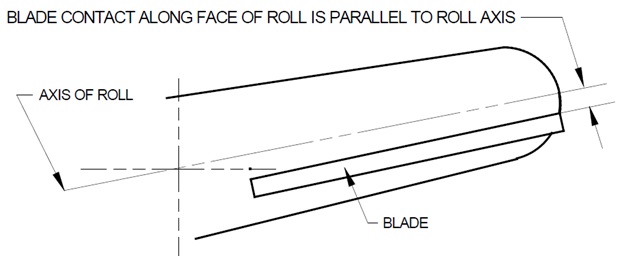

A blade is properly aligned when the blade contact across the face of the roll is parallel to the axis of the roll. If the blade is not aligned, there will be areas that do not make sufficient contact with the roll. If your overcome this geometric issue by increasing the loading forces, the outcome will be uneven and potentially damaging loading pressure across the roll face.

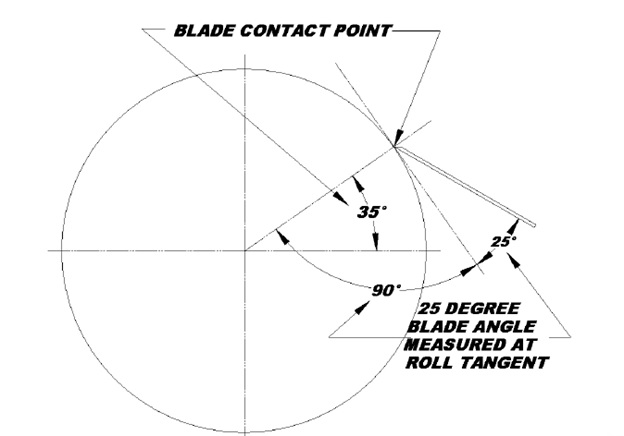

Blade angle is easiest to explain visually. For hard roll surfaces or to remove substances that stick or adhere to the roll surface, use steeper angles rather than increasing blade pressure. For soft covered rolls, using shallower angles as a way to protect the roll cover. Intuition may lead you to increase the blade angle in order to improve performance, but there is a point at which the blade angle becomes too steep to be effective and can lead to roll damage. This angle varies from application to application.