Expansion Joint Solutions for High-Pressure Applications

Often in industrial piping systems, pressure contained can exceed 300 psi (20.7 bar). When pressures rise it becomes critical that the expansion joints within the system are designed for the additional load.

Often in industrial piping systems, pressure contained can exceed 300 psi (20.7 bar). When pressures rise it becomes critical that the expansion joints within the system are designed for the additional load.

Kadant Unaflex offers the Style 200XL expansion joint as a non-metallic solution for such applications. The Style 200XL can be configured to handle pressures of up to 350 psi. This expansion joint type differs from the well-known Style 1000 Superflex expansion joints in that they have additional layers within the body of the joint and have less movement capabilities using a standard arch design.

A Style 1000 expansion joint can be configured to handle higher than normal pressures as well, but it is not as commonly used as the Style 200XL. Style 200XL expansion joints are available in multiple arch designs and open or filled arch designs.

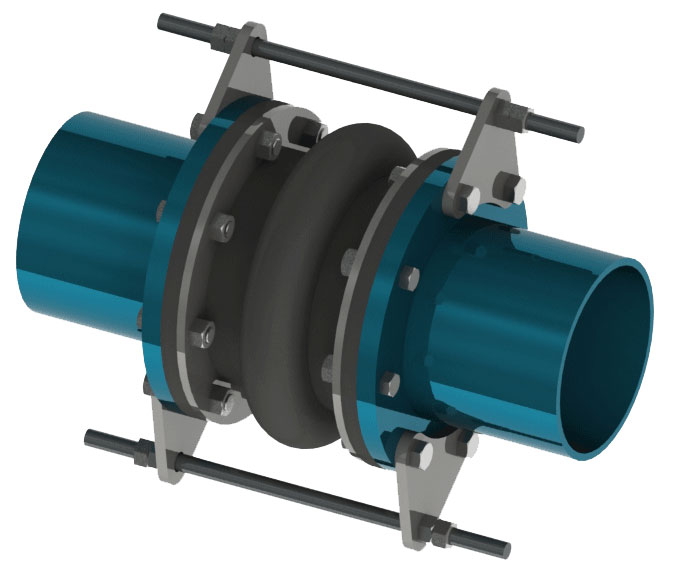

If the requirements can be met by a rubber expansion joint, there are advantages over metal including lighter weights and lower costs. Additional support configurations can be applied to the joint limiting the movements. Gimbal, hinge, and standard control unit sets are some ways to control movements in the piping system. Proper anchoring is always the best way to control movement.

If the requirements can be met by a rubber expansion joint, there are advantages over metal including lighter weights and lower costs. Additional support configurations can be applied to the joint limiting the movements. Gimbal, hinge, and standard control unit sets are some ways to control movements in the piping system. Proper anchoring is always the best way to control movement.

Outside of the rubber expansion joint category, our extensive line of metal bellows expansion joints can also be configured to exceed high-pressure application needs. A key advantage to metal bellows is the ability to accommodate high temperatures as well as high-pressure requirements. High-pressure applications may require two-ply, or three-ply bellow units as specified by our engineering team.

All our metal bellows expansion joints follow the guidelines set forth by the Expansion Joint Manufacturer’s Association. Metal bellows expansion joints utilize many types of steel, ranging from stainless steel to exotics such as Hastelloy and Inconel. Much like the rubber expansion joints, our metal bellows joints have several configurations to manage movement around the joint. Proper anchoring is always the best solution, however, hinges, gimbals, control rods, and compression sleeves may be added to the joint to manage the movement allowed.

All our metal bellows expansion joints follow the guidelines set forth by the Expansion Joint Manufacturer’s Association. Metal bellows expansion joints utilize many types of steel, ranging from stainless steel to exotics such as Hastelloy and Inconel. Much like the rubber expansion joints, our metal bellows joints have several configurations to manage movement around the joint. Proper anchoring is always the best solution, however, hinges, gimbals, control rods, and compression sleeves may be added to the joint to manage the movement allowed.