Expansion Joint Basics

Piping systems and ducting systems are constantly under stress related to thermal expansion and mechanical growth. Thermal expansion occurs when materials expand or contract with temperature changes. Mechanical growth is caused by pressure surges when the system starts up or shuts down. The rigidity of the pipes and connections do not allow for such movements without placing the material under unnecessary stress. Over time this stress will lead to fatigue and ultimately failure of mechanical equipment in the piping system. Replacing mechanical components in a piping system can be extremely expensive. Therefore, expansion joints are used to allow for these movements and help to contain the stresses within a small replaceable component. Expansion joints are manufactured in several forms and materials.

Rubber Expansion Joints

Rubber expansion joints are a cost-effective way to provide protection and contain motion to a targeted area. Rubber expansion joints are made from differing grades of polymers, some being more common. The selection of polymer or rubber is dictated by both the internal and external environment of the application. For instance, ethylene propylene diene monomer (EPDM)is a common material for expansion joints but it is not compatible with hydrocarbon-based media. Therefore, neoprene is the material to use for expansion joints when working with oils, gasoline, and other petroleum-based fluids. The selection of the correct polymer is critical to the lifespan of the expansion joint.

are a cost-effective way to provide protection and contain motion to a targeted area. Rubber expansion joints are made from differing grades of polymers, some being more common. The selection of polymer or rubber is dictated by both the internal and external environment of the application. For instance, ethylene propylene diene monomer (EPDM)is a common material for expansion joints but it is not compatible with hydrocarbon-based media. Therefore, neoprene is the material to use for expansion joints when working with oils, gasoline, and other petroleum-based fluids. The selection of the correct polymer is critical to the lifespan of the expansion joint.

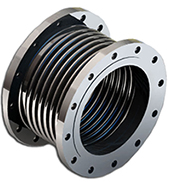

Metal Bellows Expansion Joints

Some applications do not lend themselves to the use of rubber expansion joints. Often systems require temperature allowances or pressures greater than what can be handled by rubber expansion joints. Metal bellows expansion joints offer greater pressure and temperature allowances and resistance to certain media while still protecting the system by isolating the movements and vibrations within the body of the expansion joint. Metal bellows expansion joints are manufactured using high-quality metals including all grades of stainless steel, and some exotic metals such as Inconnel® and Monel®. Metal bellows expansion joints can be built with single or double-ply bellows and can be installed using weld in nipples, fixed flanges, floating or Van Stone flanges, and raised face flanges. Configurations can include dual bellows and externally pressurized.

Some applications do not lend themselves to the use of rubber expansion joints. Often systems require temperature allowances or pressures greater than what can be handled by rubber expansion joints. Metal bellows expansion joints offer greater pressure and temperature allowances and resistance to certain media while still protecting the system by isolating the movements and vibrations within the body of the expansion joint. Metal bellows expansion joints are manufactured using high-quality metals including all grades of stainless steel, and some exotic metals such as Inconnel® and Monel®. Metal bellows expansion joints can be built with single or double-ply bellows and can be installed using weld in nipples, fixed flanges, floating or Van Stone flanges, and raised face flanges. Configurations can include dual bellows and externally pressurized.

Fabric Expansion Joints

Some applications require high movement allowance, high temperatures, and low pressures. For these applications, fabric expansion joints are the ideal solution. Ducting systems of power plants, concrete facilities, and other industries are moving high-temperature gasses at low pressures. Kadant Unaflex’s Thermaflex expansion joints are designed with steel frames combined with high tech belts to allow for large movements and high temperature while keeping your system contained. Fabric expansion joints are available in an array of frame design and belt configurations. The type of belt used is decided by the external and internal environments much like rubber expansion joints.

Some applications require high movement allowance, high temperatures, and low pressures. For these applications, fabric expansion joints are the ideal solution. Ducting systems of power plants, concrete facilities, and other industries are moving high-temperature gasses at low pressures. Kadant Unaflex’s Thermaflex expansion joints are designed with steel frames combined with high tech belts to allow for large movements and high temperature while keeping your system contained. Fabric expansion joints are available in an array of frame design and belt configurations. The type of belt used is decided by the external and internal environments much like rubber expansion joints.

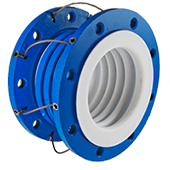

PTFE Expansion Joints

The PTFE or commonly referred to as TEFLON™ expansion joint can be combined with metal or rubber expansion joints to enhance the functionality of the joints. Many of the chemical resistant properties of the PTFE make these ideal for acidic or caustic media.

The PTFE or commonly referred to as TEFLON™ expansion joint can be combined with metal or rubber expansion joints to enhance the functionality of the joints. Many of the chemical resistant properties of the PTFE make these ideal for acidic or caustic media.

*The trademarks referenced in this blog are the property of their respective owners.